Detection is at the core of sorting. TOMRA’s high-tech sensors are like eagle eyes; they see more and are thus able to detect and provide more actionable data for your operations.

TOMRA AS A PIONEER IN SENSOR TECHNOLOGY

As the global pioneer in sensor-based sorting, TOMRA’s sorting technology continues dynamically driving the development of more reliable, and more innovative sensors, further enhancing our customer’s process.

SEEING THE UNSEEN

TOMRA’s sensor technology provides the highest efficiency, precision, and speed. Working much faster than traditional sorting technologies and prohibiting even the smallest sized particle from falling through the detection grid.

TOMRA's sensor technologies ensure high-speed processing and provide information on material, shape, size, geometry, color, defect and damage characteristics, and the location of objects.

TOMRA’s sorting principle: delivering solution tailored to your needs

To implement a precise sorting solution, we begin at the macro level of broad product application. From there, we customize the mechanical and technological needs for your particular product to fine-tune the sorting machine with the desired core sorting components. This includes sensors, electronics, software, and ejection modules.

It’s this symmetrical balance of broad technological application and customized expertise that makes TOMRA the leader in sensor-based sorting.

Core sensor technologies by TOMRA

1. Advanced Foreign Material Detector™ (AFMD)

The AFMD module incorporates technology to detect and sort on product-specific features that are difficult to identify because of similar structure or color characteristics.

2. Biometric Signature Identification (BSI)

BSI technology was designed to identify the characteristics of good products and defect products by applying light beyond the visible spectrum into the near-infrared region. It has been presented with several awards and produced new sorting opportunities for nuts, dried fruit, and other food applications

Using TOMRA BSI technology, it is possible to not only identify certain chemical and molecular differences on the surface but also within the objects inspected.

3. Camera

Our cameras recognize materials based on color, biological characteristics, and shape (including length, width, diameter, area, and other). The capabilities go beyond the visible spectrum and include infrared, ultraviolet, and other spectra imaging. TOMRA has developed high-resolution industrial cameras for the applicable spectrum that applies advanced focusing lenses for ideal optical food sorting.

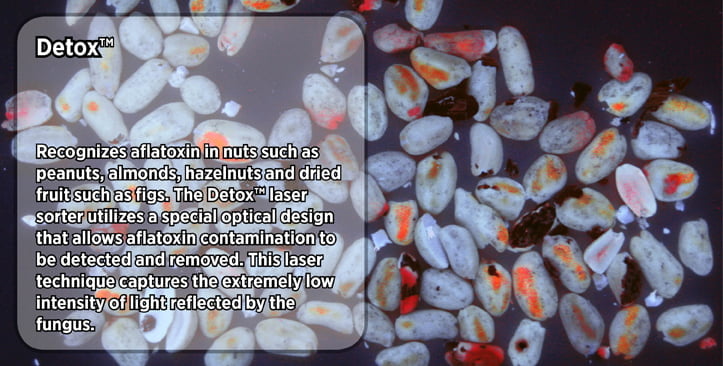

4. Detox™

This technology identifies aflatoxin in nut related products, including peanuts, almonds, hazelnuts, and dried fruits such as figs. The Detox™ laser sorter utilizes a specialized optical configuration to capture the extremely low intensity of light reflected by the fungus, enabling aflatoxin contamination to be detected and removed.

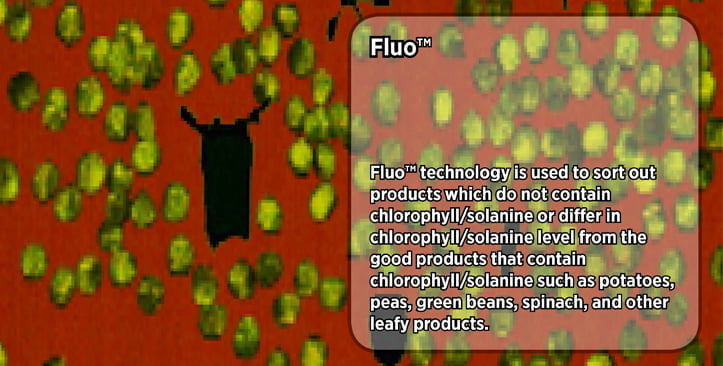

5. Fluo™

Fluo™ technology is applied to sort out products containing varying chlorophyll/solanine levels (such as potatoes, peas, green beans, spinach, and other leafy vegetables) from the defects that do not contain chlorophyll/solanine (such as stones, plastics, glass, wood, metal, rotten spots et cetera.)

6. Interactance spectroscopy

Near-InfraRed (NIR) penetrates light far into the meat and has become the preferred method to ensure accurate laboratory analysis of the meats fat content.

7. Laser

TOMRA’s laser machines sort based on color, structure, and biological characteristics. Laser scanning detects contaminants even when the acceptable products and the defects present the same color.

8. Pulsed LED

Recognizes the subtle color differences thanks to the combination of several distinct pulses in the RGB, IR, and NIR spectrums. The benefits are numerous and calibration-free equipment, increased durability, extended lifetime, high resolution of materials, and less heating needed all maximize the productivity in your line.

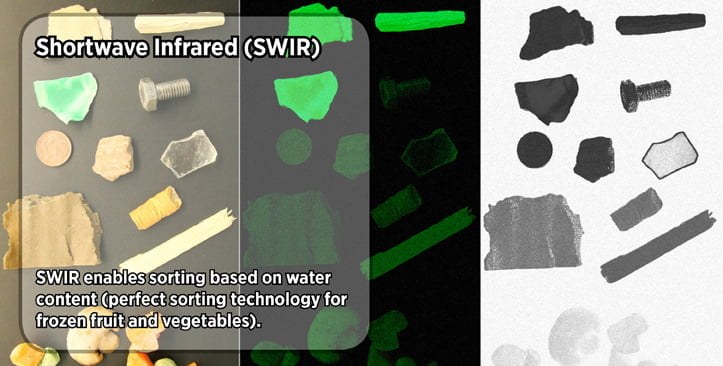

9. Shortwave Infrared (SWIR)

SWIR allows sorting based on water content, creating a contrast between water-based products and other materials. This technology is very effective for the sorting of fruits and vegetables.

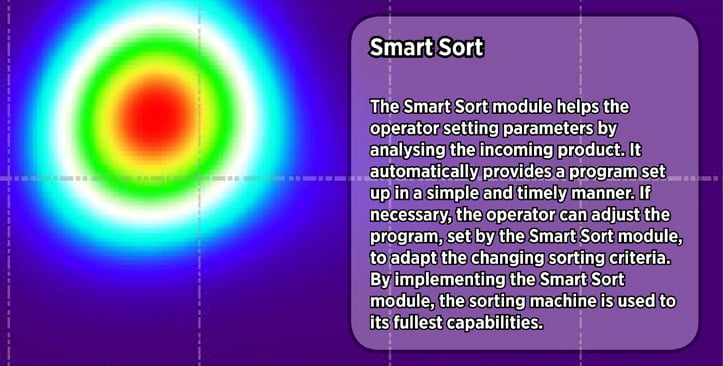

10. Flex & Smart sort

The Smart Sort module helps operators establish parameters by analyzing the incoming product and automatically providing a program setup. If necessary, the operator can adjust the program to adapt the sorting criteria. By implementing the Smart Sort, the sorting machine is used to its full capabilities in a simple and timely manner.

11. X-ray

This technology detects based on product density, regardless of the size, moisture, or contamination level.